The D‑Fine Double Diamond™ Polishing System gives you the freedom to effectively polish both porcelain and hybrid composite surfaces with the same polisher.

D-Fine™ Double Diamond Polishing System for Hybrid Composites and Porcelain

- Description

- Clinical Techniques

- Resources

- Instructions for Use / SDS

- Product Configurations

- Testimonials

Description

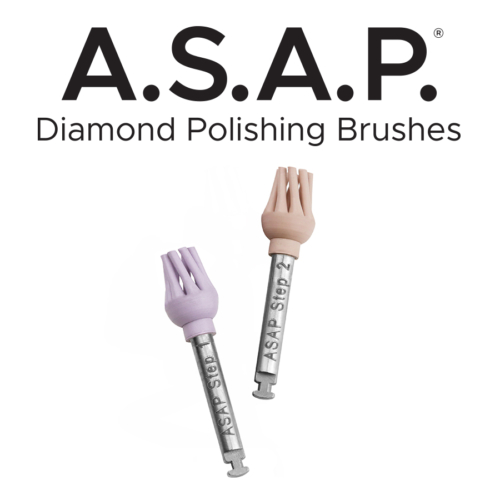

Each Primary Polisher (purple) is embedded with diamond particles (average particle size 45 microns) to help create a smooth surface topography on hybrid composites and porcelain. After the initial polish comes the final high shine polish. D‑Fine Double Diamond™ Final High Shine Polishers (orange) have a small 5-micron diamond particle size and more diamond particles than any other polisher. This means you can achieve a better shine in less time.

- 2 step diamond polishing system for hybrid composites and porcelain

- Primary Polisher (purple) 45μ diamond and Final High Shine Polisher (orange) 5μ diamond

- When applied properly, polishers will splay, closely hugging the surface topography and polishing (without the risk of ditching) the gingival margins

- Autoclavable up to 275°F

- Allow multiple polishes without compromising the performance

- Using gentle pressure will extend the life of the polisher

Clinical Techniques

Photography and dentistry courtesy of Dr. Gildo Santos

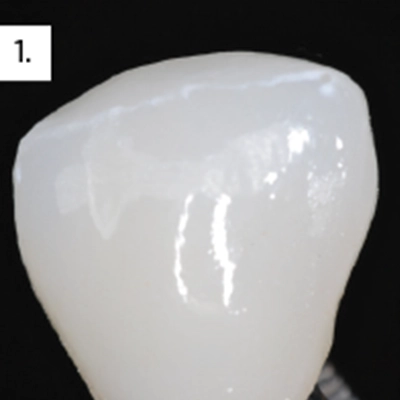

Facial view of e-max crown after occlusal adjustments. Note matte surface caused by the adjustments at the buccal-incisal area.

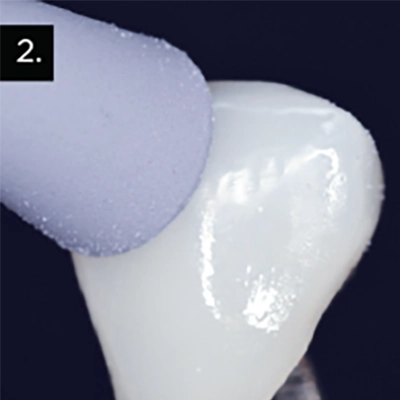

Using a light wiping motion, the D-Fine Double Diamond Primary Polisher (45 micron diamond particles) is used to create the initial polish.

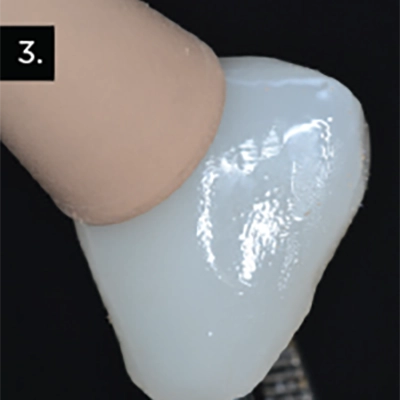

Using light pressure with the D-Fine Double Diamond Final High Shine Polisher creates the final high-gloss finish. Water spray is recommended.

Instructions for Use / SDS

| INTENDED USE: Dental finishing and polishing points intended as a medical device for the purpose of final polishing of all composite and ceramic restorations. |

TECHNIQUE STEP 1: D-FINE Double Diamond Primary Polishers (purple) 1. Use a finishing diamond/carbide to contour the composite surface. 2. Select the appropriate D-FINE Double Diamond Primary Polisher. 3. Using a wiping motion, at 7,500 – 10,000 rpm, and with light to moderate pressure and water spray, apply the primary polisher to the restorative surface. A smooth silky surface will appear in approximately 30 seconds. |

STEP 2: D-FINE Double Diamond Final High Shine Polishers (orange) 1. Select the appropriate D-FINE Double Diamond Final High Shine Polisher. 2. Again, with light to moderate pressure and water spray, apply the Final High Shine Polisher to the restorative surface with a wiping motion, until a high gloss finish is achieved. NOTE: Failure to follow this technique will lead to premature degradation of the polishers. |

RECOMMENDED STERILIZATION D-FINE Double Diamond polishers should be steam autoclaved only up to 275°F/135°C. Product is not sold in sterile condition. |

Click here to view the D-Fine Double Diamond IFU/SDS.

Product Configurations

D-Fine Double Diamond Starter Kit:

- 4 x primary polisher, 4 x final high shine polisher (1 of each shape): Shapes 04, 05, 06, 08.

D-Fine Double Diamond Primary Polisher Refill Kit:

- 12 x primary polisher. Specify 1 shape: Shape 04, Shape 05, Shape 06, Shape 08

D-Fine Double Diamond Final High Shine Polisher Refill Kit:

- 12 x final high shine polisher. Specify 1 shape: Shape 04, Shape 05, Shape 06, Shape 08

Testimonials

The D-Fine Double Diamond and Groovy Diamond Polishing Systems are my gold standard for finishing and polishing composite restorations.