Affinity™ Monophase Hydroactive Impression Material

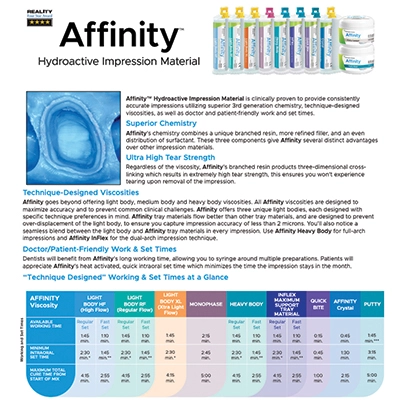

Description

- Cost-effective single-phase impression material

- Maintains properties of polyether such as a gum-like consistency, high durometer cure, and high tear strength

- Ideal for implant impressions, endentulous, partial impressions and fabrication of clear aligners in orthodontic treatments

- Combines a unique branched resin, more refined filler and even distribution of surfactant for enhanced accuracy

- Enhanced hydrophilicity for excellent performance in the presence of moisture, especially with subgingival preparations

- Available in regular set only

Clinical Technique

Resources

Instructions For Use / SDS

Click here to view the Affinity Monophase Instructions for Use / SDS.

Product Configurations

- 2-50mL cartridges, instructions/SDS

- with mixing tips

- without mixing tips

- 12-50mL cartridges, instructions/SDS

- without mixing tips

FAQ

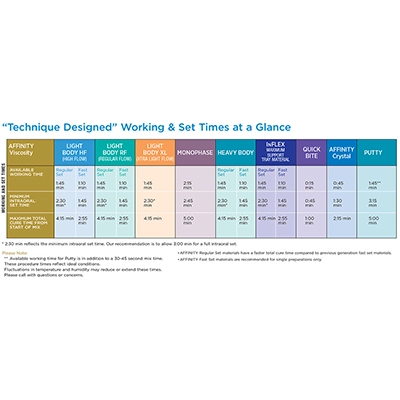

The working time of Affinity Regular Set material is 1:45 mins with a setting time of 2:30 mins.

Affinity Fast Set materials have a working time of 1:10 mins and a set time of 1:45 mins.

Only Affinity uses branched resin chemistry for 3-dimensional cross-linking resulting in a higher tear strength, refined fillers, and an even distribution of surfactant. Other impression materials use linear resin chemistry with an uneven distribution of surfactant resulting in less accurate impressions that are more prone to tearing of the thin interproximal and sulcus fins.

Light and heavy body materials from another brand may be mixed but strict attention must be paid to the working and set times as they need to mimic or exceed Affinity’s.

Always keep the tip of the mixing tip fully immersed in the Light Body fully as it is syringed around the prep sites.

It is important to work quickly when loading Quad-Trays. Dispense Affinity InFlex in an S-pattern onto the non-prep side after running a bead of material around the periphery of the tray. Immediately turn the Quad-Tray over and repeat on the prep side.

If using Fast Set, switch to Affinity Regular Set impression material. Do not attempt to adjust the temperature of the material in order to slow down the set.